Responsible waste management

At AEL, our comprehensive Waste Management policy emphasises alignment with sustainable waste management practices, circular economy principles, and compliance with environmental regulations. Through continuous improvement and innovation, we strive to reduce our environmental impact and contribute to a cleaner, more sustainable future.

Pursuing Sustainable Waste Management

We conduct regular waste audits to identify opportunities for enhancing waste performance and develop tailored action plans to systematically reduce waste generation across operations. We have set quantified targets to minimise waste and rigorously track our progress to ensure that the goals and ambitions are met. Continuous investment in innovation and R&D helps us discover new ways to reduce and manage waste more effectively. We also provide waste reduction training to employees, fostering awareness and promoting responsible waste management practices.

Waste Management Focus Areas

Minimising waste generation

Maximising resource efficiency

Increase recycling and reuse

Responsible disposal of non-recyclable materials

In FY 2024-25, AEL achieved a significant milestone by diverting 99% of waste generated through reuse and recycling efforts, owing to strategic initiatives undertaken by respective businesses to ensure proper handling, storage, and disposal of waste generated from their premises.

Category-wise Waste Disposal and Recycling

Waste Category

Waste Handling and Disposal

Plastic Waste

Recycled by various businesses such as through Reverse Vending Machines (RVMs) installed at Mumbai and Ahmedabad airports.

E-Waste

Recycled/returned to the Original Equipment Manufacturers (OEMs) for repair, refurbishment, or material recovery, in compliance with applicable statutory obligations.

Construction & Demolition Waste

Reused as aggregate in new concrete, for paving blocks and construction of roads.

Other Non-Hazardous Waste

Mainly includes overburden from our mining operations - repurposed for backfilling, thereby facilitating mine reclamation efforts.

Hazardous Waste

Safely collected and sent to authorised vendors for recycling or disposal, as applicable in accordance with laws and regulations.

Zero Waste to Landfill

Multiple businesses under AEL are working towards achieving zero waste to landfill status. To accomplish this, they have conducted detailed waste audits to identify opportunities for reducing waste generation, while managing most of the waste generated through reuse and recycling methods. Hazardous waste is safely collected and sent to authorised vendors for recycling or disposal in compliance with applicable laws and regulations. To ensure no waste ends up in landfills, these businesses adopt innovative waste management approaches, including various methods to transform waste into useful items.

CASE STUDY

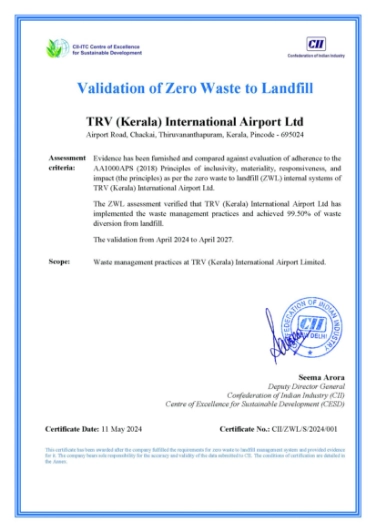

Thiruvananthapuram Becomes the first Indian Airport to be Certified for Zero Waste to Landfill

Implementing zero waste to landfill at airports is essential for reducing environmental impact, saving costs, complying with regulations, enhancing public image, and improving operational efficiency. By minimising and diverting waste sent to landfills, airports can significantly lower pollution, conserve resources, and demonstrate leadership in sustainability. This approach not only benefits the environment but also attracts environmentally-conscious travellers and businesses, while streamlining waste management processes and potentially reducing operational costs.

Waste Management Strategy

Thiruvananthapuram International Airport (TIAL) has adopted a comprehensive waste management strategy based on the cradle-to-cradle concept. The core focus of TIAL's strategy is the adoption of the 5R principles: Reduce, Reuse, Reprocess, Recycle, and Recover. This prioritises waste minimisation and ensures that all generated waste is managed efficiently.

Material Recovery Facility (MRF)

All waste generated at TIAL is managed at a dedicated Material Recovery Facility (MRF). The waste management process at the MRF involves five stages.

- Collection: Gathering waste from various sources within the airport

- Identification: Categorising waste types for appropriate processing

- Segregation: Separating waste into recyclable and non-recyclable materials

- Storage: Safely storing waste until it can be processed or disposed of

- Responsible Disposal: Ensuring waste is disposed of in accordance with national rules and regulations

Achievements and Recognition

Through effective implementation of its waste management strategy, Thiruvananthapuram International Airport has become India's first airport to earn the Zero Waste to Landfill (ZWL) recognition from the Confederation of Indian Industry (CII). This recognition showcases TIAL’s dedication to sustainability and its commitment to environmental stewardship.

By embracing the 5R principles and implementing a strong value chain system, TIAL has achieved an impressive landfill diversion rate of 99.50%. This achievement sets a new benchmark in waste management among Indian airports. The benefits of this initiative include:

- Environmental Impact: Significant reduction in pollution and conservation of resources

- Cost Savings: Reduced waste management costs and potential operational savings

- Regulatory Compliance: Adherence to national waste management regulations

- Enhanced Public Image: Improved reputation among environmentally-conscious travelers and businesses

- Operational Efficiency: Streamlined waste management processes leading to better operational efficiency

The zero waste to landfill certification of Thiruvananthapuram International Airport demonstrates a successful model of sustainable waste management. By adopting the 5R principles and focussing on waste minimisation, TIAL has set a high standard for other airports to follow. This case study highlights the significant environmental, economic, and operational benefits of implementing a zero waste to landfill policy, showcasing TIAL’s leadership in sustainability and commitment to a greener future.

CASE STUDY

Waste to Wealth: Utilization of Fly Ash and Pond Ash in Road Construction

The disposal of industrial byproducts such as pond ash and fly ash presents significant environmental challenges. Our Roads business addresses this issue by transforming these byproducts into valuable resources for road construction, thereby minimizing waste and promoting sustainability.

Pond Ash Utilization

Pond ash, a byproduct of coal-fired power plants, is effectively utilized in road construction for various purposes. Its incorporation into road bases offers several environmental benefits:

- Reduces Environmental Impact: By using pond ash, we minimize the need for natural resources, thereby reducing the environmental footprint of road construction.

- Conserves Water: The use of pond ash helps in conserving water resources during construction.

- Protects Topsoil: By substituting pond ash for natural materials, we have conserved more than 50,84,720 metric tonnes of topsoil, protecting it from degradation.

- Prevents Vegetation Loss: Utilizing pond ash helps in preserving vegetation in construction areas.

This approach is both cost-effective and eco-friendly, enhancing road durability and extending lifespan, which ultimately reduces the need for frequent maintenance.

Fly Ash Utilization

Fly ash, another byproduct of coal combustion, is extensively used in road construction. Its applications include:

- Road Bases: Similar to pond ash, fly ash is used in the construction of road bases, providing a stable foundation

- Concrete Mix Formulation: Fly ash is employed in concrete mix formulations, enhancing the durability of concrete structures. This reduces cement consumption, minimizing environmental impact

- The use of fly ash in road construction promotes sustainable practices by reducing waste and conserving natural resources

Environmental and Economic Benefits

The utilisation of pond ash and fly ash in road construction offers numerous benefits:

- Environmental Preservation: By repurposing industrial by-products, we reduce the environmental impact of waste disposal and conserve natural resources

- Economic Value Creation: The use of these byproducts is cost-effective, reducing the overall cost of road construction and maintenance

- Sustainability: This practice supports sustainable development by promoting the use of eco-friendly materials and reducing the carbon footprint of construction activities

Our Roads business demonstrates a commitment to sustainability by transforming industrial byproducts into valuable resources for road construction. The use of pond ash and fly ash not only addresses environmental challenges but also promotes economic value creation and sustainable development. This case study highlights how innovative practices in road construction can lead to significant environmental and economic benefits, setting a precedent for future projects.