Wastewater management

At APSEZ, we acknowledge the importance of responsible and safe management of wastewater – from generation to final disposal, as part of our responsible water management strategy. Our efforts are focussed around the principles of wastewater reduction and recycling/reuse, with the objective of reducing the wastewater for eventual disposal.

In line with our commitment towards minimising the potential adverse impact of our wastewater management practices on the environment and human health, we:

- Undertake actions to prevent or reduce the generation of wastewater to the extent possible

- Recycle/reuse wastewater as and when needed

- Modify our operational systems and processes to ensure the above

- Manage any remaining wastewater in an environmentally responsible manner

Wastewater Management Initiatives

Implementation of zero liquid discharge (ZLD) projects to increase the efficiency of our effluent treatment plants (ETPs)

Successful recycling of 98% of the total wastewater generated in FY 2024-25

Boosted the reuse of waste-water. Over 1,111 ML of treated wastewater used in FY 2024-25

Wastewater Management Hierarchy Principle

We have adopted this principle for sustainable management of water to nurture environmental conservation and sustainable development. The principle is centred around prioritisation of source reduction, reuse and recycling, treatment, and disposal, to ensure that wastewater is managed in a responsible, sustainable and safe manner.

Water Conservation Initiatives at APSEZ

- Annual audits of water management process

- Monthly water consumption monitoring at our key business units to identify any sudden increases in water usage

- Use of wastewater from various sources for operational activities that do not require drinkable water, to reduce dependence on freshwater

- Implementation of localised water strategies at individual sites

- Exploration of alternative water sources, and investigation into the use of treated wastewater obtained from other industries

- Installation of rainwater harvesting systems at all sites to mitigate the risk of water scarcity

- Active engagement with suppliers and vendors through meetings and quarterly reviews, to drive collective action and promote water conservation practices that align with APSEZ's overall water management strategy.

CASE STUDY

Commissioning 450 KLD ETP with advanced treatment facility with increasing water recycling capacity at Adani Hazira Port Limited

-

Objective: Increasing wastewater treatment capacity as well as wastewater recycling capacity of the Port and reducing natural consumption.

-

Project description: Adani Hazira Port Limited is a multi-cargo Port operator, Dry bulk, Liquid and Containerised cargo are handled and stored at this Port. The Port has developed a world-class infrastructure for Liquid Cargo receiving, exporting, storage and evacuation with automation facility. The Liquid Terminal has 219 nos. of Storage tank and has 6.20 lakhs KL storage capacity. During operation of Liquid Terminal, effluents are generated in cleaning of pipelines and tanks. For efficient treatment and recycling of generated effluent, an advanced type upgraded 450 Kilo Litre per Day treatment capacity of Effluent Treatment Plant (ETP) is installed featuring advanced treatment technologies and the operation of this plant commenced on January 9, 2025.

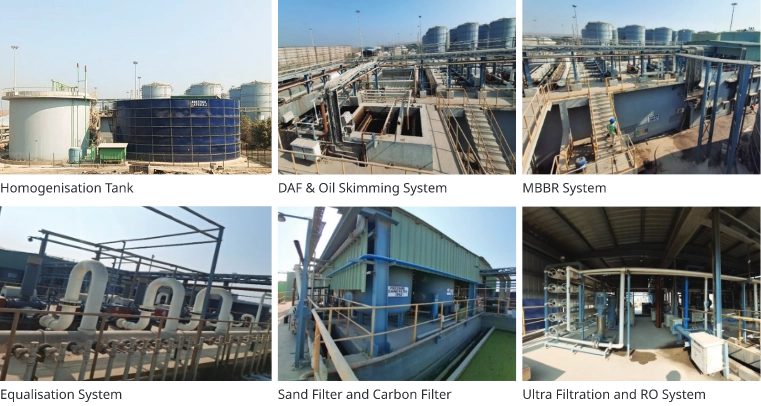

This facility includes systems for homogenisation, equalisation, oil and grease removal, dissolved air flocculation, and anaerobic digestion (UASB) with a biogas power generator. Additionally, it incorporates an aerobic digester-MBBR, tube settler, screw press system, sand filter, carbon filter, ultra-filtration unit, and reverse osmosis system. ETP also aims to minimise climate impact by utilising biogas (~70% methane) in the biogas generator and harnessing the energy produced within the plant. 70% of total effluent is recycled after final treatment through reverse osmosis process and the quality of this water is as good as drinking water.

-

Activity: Adani Hazira Port Limited has implemented a 450 Kilo Litre per Day treatment capacity of Effluent Treatment Plant (ETP) featuring advanced treatment technologies. This facility includes systems for homogenisation, equalisation, oil and grease removal, dissolved air flocculation, and anaerobic digestion (UASB) with a biogas power generator. Additionally, it incorporates an aerobic digester-MBBR, tube settler, screw press system, sand filter, carbon filter, ultra-filtration unit, and reverse osmosis system.

A state-of-the-art laboratory is also part of the ETP to monitor its performance. The plant is equipped with online sensors to track pH, BOD, COD, and TSS parameters. Designed to maximise the recovery of reusable water from wastewater, ETP also aims to minimise climate impact by utilising biogas (~70% methane) in the biogas generator and harnessing the energy produced within the plant.

Effluents are produced as a result of operational activities at the Liquid Terminal, primarily stemming from the cleaning of pipelines and Liquid Cargo Storage Tanks. The terminal is equipped with decentralised effluent storage facilities. Initially, the effluent is collected in Oil Water Separator (OWS) Tanks located within each enclosure, with each enclosure housing two OWS Tanks, each having a capacity of approximately 50 KL. The effluent is subsequently transferred from the OWS Tanks to Slope Tanks, with each enclosure also containing two Slope Tanks, each with a capacity of around 90 KL. In total, the Liquid Terminal has 25 OWS Tanks and 25 Slope Tanks, with additional OWS/Slope Tanks currently under construction. All Slope Tanks are interconnected to the Effluent Treatment Plant (ETP), and effluents are conveyed to the ETP from the Slope Tanks via a dedicated pipeline network

The laboratory is equipped with various instruments, including a pH meter, Hot Air Oven, Muffle Furnace, Analytical Balance, Spectrophotometer, Centrifuge, Distillation Apparatus, COD Analyser, BOD Incubator, DO meter, Orsat Apparatus, Glass Desiccators, Magnetic Stirrer, and Phenol Distillation Assembly

-

Methodology: The treatment scheme involves Primary, Secondary, Tertiary and Advanced Treatment. In primary, homogenisation, Oil and Grease removal through Oil skimmer and Dissolved Air flocculator, Coagulation, flocculation, equalisation, Primary sludge removal, Anaerobic Digestion through UASB, Aerobic Digestion through MBBR, Secondary Sludge removal, Screw Pressing of Sludge, Sand filter and carbon Filter treatment, Ultrafiltration and Reverse Osmosis. The RO product is reused in process and RO reject is disposed of in sea.

-

Project cost: The commissioning of the Effluent Treatment Plant was completed on November 5, 2024, with an approximate project cost of ₹25.24 crore.

-

Estimated project benefits: The ETP project effectively treats up to 450 kilolitres per day of cargo-contaminated wastewater and recycles up to 300 kilolitres per day of wastewater generated at the Port. The biogas produced during anaerobic digestion in the biogas generator is utilised to generate energy, which is then reused in the ETP operation. This initiative promotes wastewater recycling, pollution prevention, and the use of methane to mitigate global warming.